This peanut butter production line can provide you with the most healthy and green food by the most effectual & most intelligent technology, which consists of the roaster, cooler, peeler, grinder, mixer, degasser and packer etc.

Using the most advanced technology, yoocco has made many improvements and optimizations to the core equipment peanut butter grinding machine in the complete set of equipment, the processing fineness is further improved, and the service life is longer.

We can customize the machine according to the customer’s output, and can also measure and arrange according to the customer’s actual site to realize automatic production.

Produces the highest quality stabilized, granular and regular peanut butters。

We have already exported many peanut butter production lines to many foreign countries, and have full experience in manufacturing and after-sales service. Can make full use of the workshop space, and strive to make the process more reasonable.

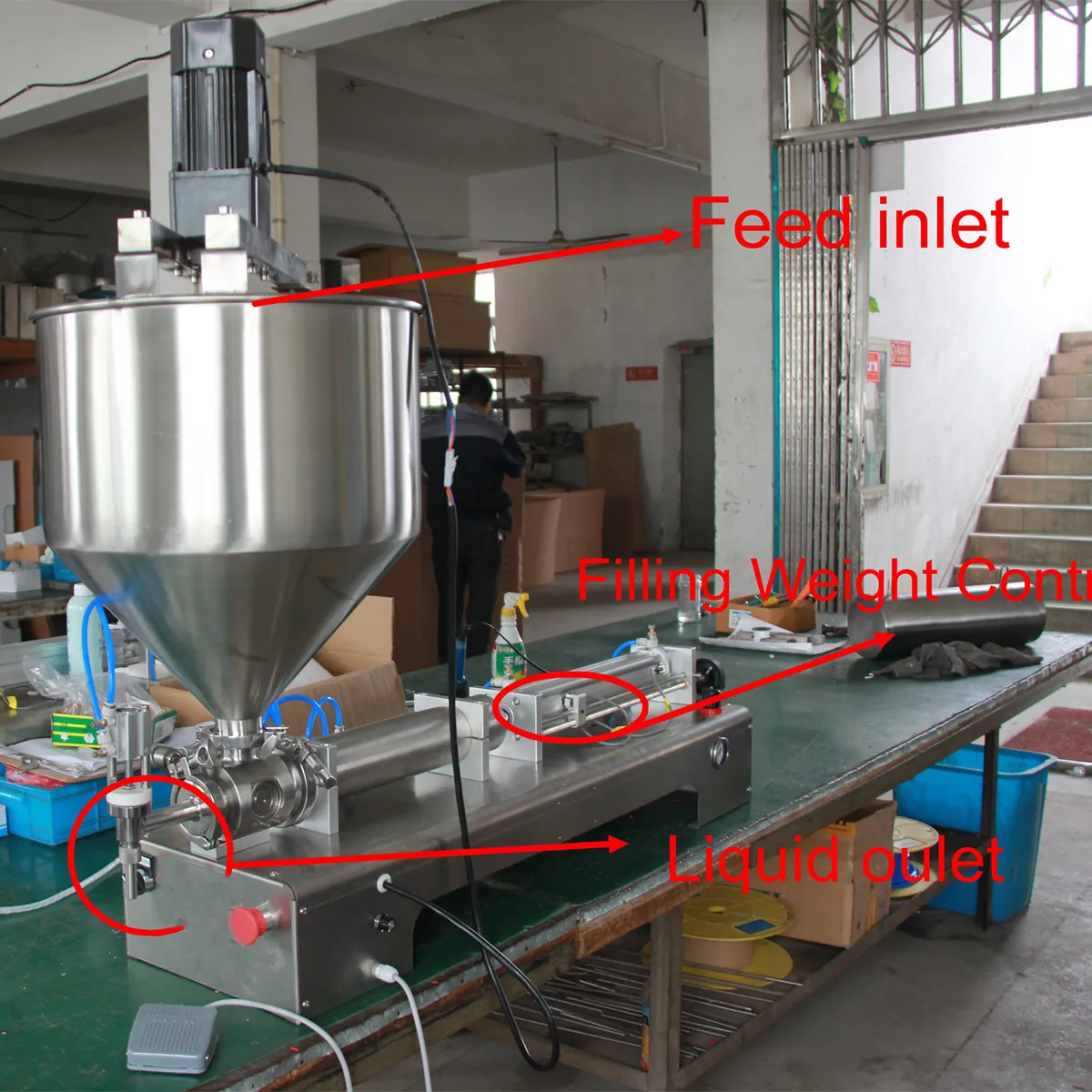

Peanut shelling-peanut kernels-Cleaning-Roasting-Cooling-Peeling-Grinding sauce-Mixing-Cooling-Vacuum degassing-Filling

1. Under high temperature baking, the high hydrocarbons, sulfur-containing compounds, pyrazine compounds, etc. generated by the carbonyl ammonia reaction (Maillard reaction) endow the oil with a rich aroma.

2. Baking temperature and time, protein denaturation. The cell walls are destroyed, and finely dispersed oil droplets are aggregated and released. At the same time, the protein has changed its spatial conformation due to denaturation, breaking the binding and binding of protein and oil, which is conducive to the extraction of oil.

3. The carbonyl ammonia reaction and caramelization reaction caused by baking make the oil form a bright and attractive orange-yellow color

170 degrees Celsius, 25-30 minutes

The oil content of peanuts is 40%-55%.

Since the sulfur-containing compounds, pyrazines and other aroma substances similar to small milled sesame oil formed by baking are not resistant to high temperature, these aroma substances will be destroyed under high temperature for a long time, lose their unique aroma, and will also produce scorch. Therefore, the roasted nuts must be forced to cool down to below 60°C in a timely manner.

Remove the air (oxygen) in the feed liquid, inhibit the oxidation of browning, pigments, vitamins, aroma components and other substances, and prevent quality degradation; remove the suspended particulate gas attached to the feed liquid, inhibit the floating of the particles, and maintain a good appearance; prevent Foaming affects sterilization during canning and high temperature sterilization; reduces corrosion to the inner wall of the container.

If you have any questions about our machine, please do not hesitate to contact us.

Our staffs are well-trained to provide our customers with solid professional advice and we are here to provide flexible and professional solutions. Please see the process we follow below:

You can send us an email or call us to discuss your requirements, We will ask you questions such as: You can send us an email or call us to discuss your requirements, We will ask you questions such as: quantity, style of packaging, printing, finishing, what daye you need, delivery and postcod …

When you send a quote request with all machine specifications, our product experts will begin to prepare your quotation. A simple quotation can be ready and returned to you in as little as 1 working days.

May some customers can’t confirm our machine can process the raw material of their have, so will send us the material , then we will test the raw material on our machine.

When you are satisfied with the quotation and are ready to continue, please use our secure payment portal, which will be provided by our product experts.

Before bulk manufacture, our sales manager will confirm all the technology parameter with you, to confirm everything is correct.This will send you an email to confirm.

Once you approved everything, we will go ahead your bulk order! Throughout this stage, our product experts will keep in touch with you and keep abreast of the latest situation of manufacturing!

Every set of our chocolate machinery will be tested by our mechanical engineer and electrical engineer before shipping. For production lines, we even test the machinery with oil or chocolate. Moreover, our sales will provide photos and videos to you before settling balance payment;

We will organise all courier or shipment logistics and paperwork. For small orders, we use air freight, and for large orders it is more cost effective to ship by sea.

Yoocco Has More Than 10 Years Experience In Nuts Processing Machinery, Especially Nut. Subscribe To Our Newsletter To Get The Latest Industry News And New Products.

We will contact you within 1 working day, please pay attention to the email with the suffix “@yoocco.com”.